/ From: / Review:1430

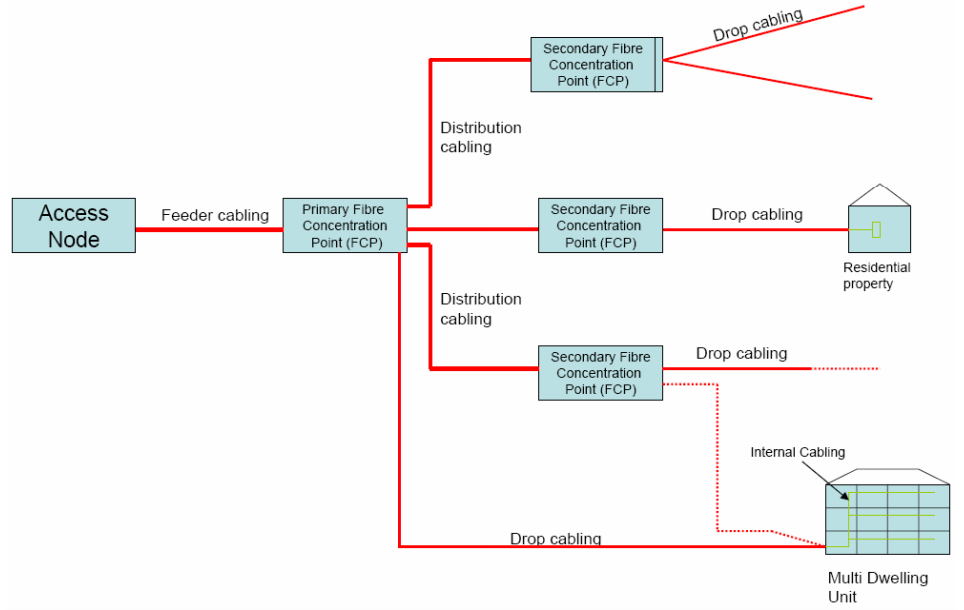

FTTH (fiber-to-the-home) has replaced the existing copper cables in appliances such as telephone wires by bringing about a unique system of delivering optical fiber to the homes and offices directly from the switching equipment of the operator. Their network is spread between both outdoor and indoor sections of the house, and hence, they require various different types of fiber optic cables. A drop cable forms a vital part in this network of FTTH cables, which helps complete the network from the subscriber’s end by connecting the subscriber’s premises with the distribution cable’s terminal. FTTH drop cabling solutions will be provided in this tutorial.

FTTH Drop Cabling Overview

Drop cabling forms the final external link to the subscriber and runs from the last FCP to the subscriber building for a distance not exceeding 500m which is reduced considerably in high-density areas. Drop cables are used for subscriber connections, usually contain a number of fibers but may include additional fibers for backup or for other reasons. Drop cable normally the only link to the subscriber lacking network diversity.

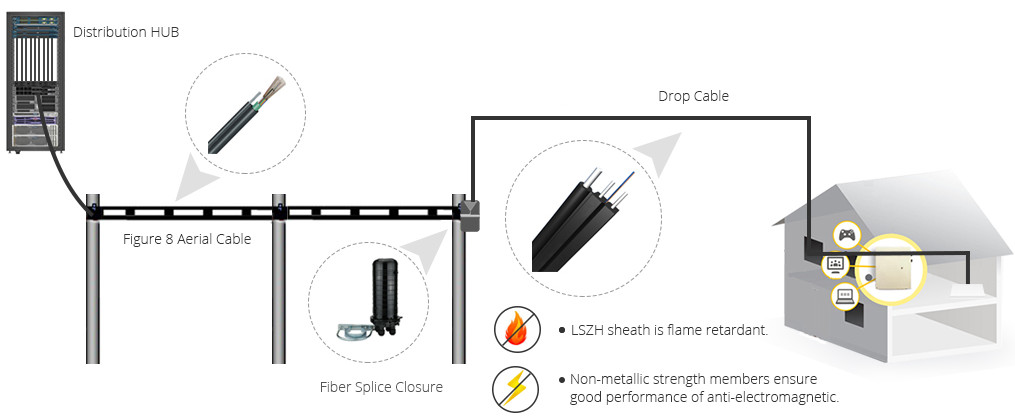

For underground networks, the drop cabling may be deployed within small ducts, within micro-ducts or by direct burial to achieve a single dig and install solution. Overhead drop cables will feed from a nearby pole and terminate at a chosen point on the building for onward routing to the termination unit. In either case, the cable assembly may be pre-terminated or pre-connectorized for rapid deployment and connection, as well as to minimize disruption during installation.

FTTH Drop Cable Types

Drop cables come in three main types: direct install, direct buried and aerial. Since these cables are present in the outdoor, they have a smaller diameter and low fiber count. They can be installed underground, above ground or overhead.

Direct Install Cables

Direct install cables are installed into ducts, usually pulled, pushed or blown. The structure can be non-metallic with an external/internal sheath, or a double sheath: one internal low-smoke zero-halogen (LSZH) and one external PE. Cables are available from 1 to 36 fibers (typically 12 fibers). The fiber elements can be loose tubes, micro sheath, or blown fiber units.

Direct Buried Cables

Direct buried cables are available in two constructions: non-metal, or with metal protection (corrugated steel). The advantages of metal-protected cables are their extremely high crush resistance and high-tension loading. New non-metal strain-relief and protective sheets have been developed to give non-metal direct buried cables similar performance capabilities to that of metal-protected cables. On average, non-metal cables are lower in cost. Direct buried drop cables are available in fiber counts from 1 to 12 (typically 2—4).

Aerial Cables

One aerial drop cables are continuation of feeder or distribution networks, e.g. optical ground wire (OPGW) or all dielectric self-supporting (ADSS). OPGW cables are mainly used in power line connections. Another aerial drop cables are short-span drop cables, e.g. Figure-8, flat or circular Aerial cables are designed to a specific tensile load, which is determined by span length and environmental conditions. The Figure-8 cable consists of an optical cable with a steel wire embedded in the same jacket. Typical fiber counts are 2 to 48. All the above cables can be pre-connectorized. This is an advantage during installation as time spent in the home is reduced and also aid planning. The fiber elements can be loose tubes, micro sheath or blown fiber units.