/ From: / Review:1774

With the increasing demands on port density on fiber connectivity in today's data centers, changes of fiber optic components are on the way. Fiber Optic connectors, as one of the most important components used in fiber connectivity, are also changing to better satisfy these demands.

The Need for High Density

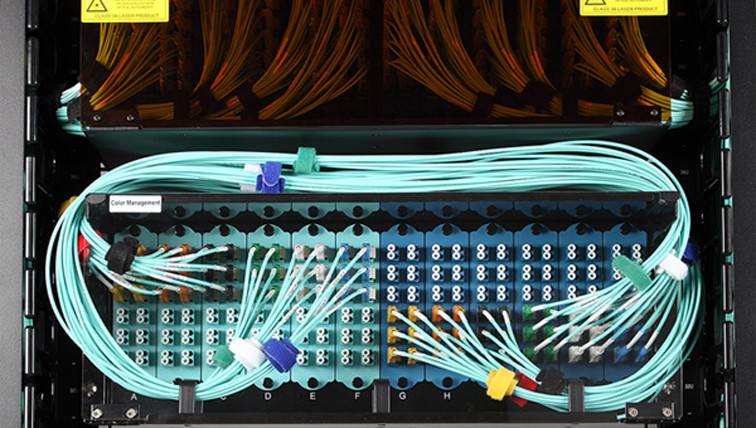

As a result of the vast proliferation of virtualization and cloud implementation, the trend toward higher-density in data center has been accelerating in recent years. The higher density fiber connectivity solutions give data center operators greater flexibility and allow them to more efficiently and more cost effectively manage the explosive growth in the number of fiber connections.

Commonly Used Connector Options for High-Density Applications

For duplex connectivity in data center, the LC duplex connector is the most commonly used small form-factor connector since the 10G infrastructure is widely deployed in today's data centers. The most typical application of LC duplex connector is to use with a SFP/SFP+ transceiver.

Although LC duplex connector is small and compact, it still cannot satisfy the demands on a greater number of connections in a smaller space. In this case, the multi-fiber connectors, namely MPO or MTP connector is applied to meet these requirements. The MPO/MTP connector which is design for parallel fiber transmission helps users achieve high bandwidth without adding the expensive fiber to their existing infrastructure.

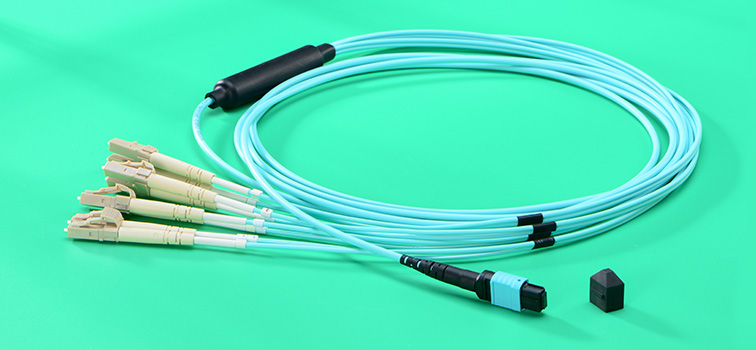

In addition, harness cable assemblies pre-terminated with one MPO/MTP connector on one side, and several LC duplex connectors on the other side are ideal for high-speed 40/100G applications. For instance, an 8-fiber MTP to 4 duplex LC harness cable can be used to break out a 40G link to four 10G links.

Improved Designed Connector Options for High-Density Applications

Everyone who work at high-density cabling may know that quickly removing and replacing connector in the high-density patch panels seems a daunting task. Without a specific tool, you almost cannot complete this task smoothly. However, it's very inconvenient that you have to use an extra tool to do this everytime. Thus, some vendors launched some special and improved designed connectors to address this issue. These connectors are mainly designed based on the commonly used LC and MPO/MTP connectors but more suitable for high-density fiber cabling.

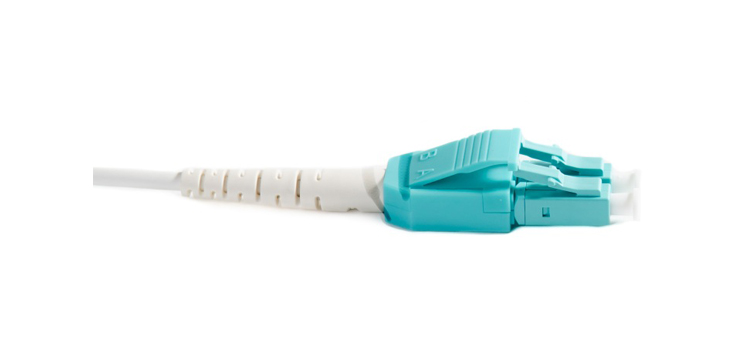

Push-Pull Tab LC & MPO Connectors

Push-pull connectors are suitable for high reliability and high quality applications where a simple yet fast method to connect/disconnect is required. The push-pull connectors greatly simplify the use of fiber connectivity when manual access to the release slider and rear portion of the connector is restricted. The common type push-pull connectors are push-pull LC connectors and push-pull MPO connectors, as shown below:

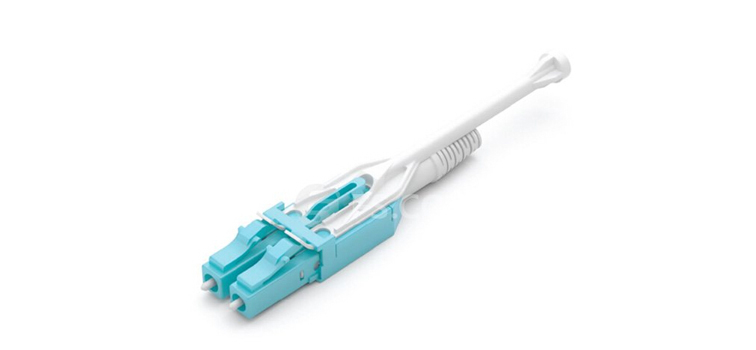

LC Uniboot Connectors

LC uniboot connector provides easier polarity reversal and higher cabling density as it allows the fiber polarity to be reversed at the time of cable assembly installation without exposing the fibers or requiring any tools. In addition, cable assemblies with LC uniboot connectors has a more compact design that there is just a single 2-fiber round cable housing in a boot. Thus, when compared to traditional duplex zipcord assemblies, it can greatly reduce cable management space by about 70%.

Uniboot LC Connectors With Push-Pull Tab

The above contents describe the benefits of push-pull tab connectors and LC uniboot connectors. So, why not put them together? The uniboot LC connector with push-pull tab is such a good "alliance" of LC uniboot and push-pull tab as it incorporates the advantages of both. However, the price may be more expensive than either of uniboot LC or push-pull tab connector.

Conclusion

The call for "high density" is rising in today's data centers. To choose a right and cost-effective fiber connectivity solution that meets the demand on high density is important to every data center operator. This paper offers several popular and ideal connector options for today's high-density fiber connectivity. You may find one you need from this paper or contact us for more information: sales@gelink.com.cn