/ From: / Review:1562

As fiber to the home (FTTH) service is rapidly increasing its popularity throughout the world, construction work to lead optical drop cable into houses needs to be streamlined. In such construction, field assembly connectors are widely used due to the applicability to cable wiring and compact bodies which are easily stored in optical fiber housings such as optical network units (ONUs). Thus field assembly connectors are attracting worldwide attention not only from the FTTH market but also from the optical LAN market for their capabilities. But how much do you know about field assembly connectors? Read this article and you will get more knowledge about field assembly connectors.

Field Assembly Connectors Overview

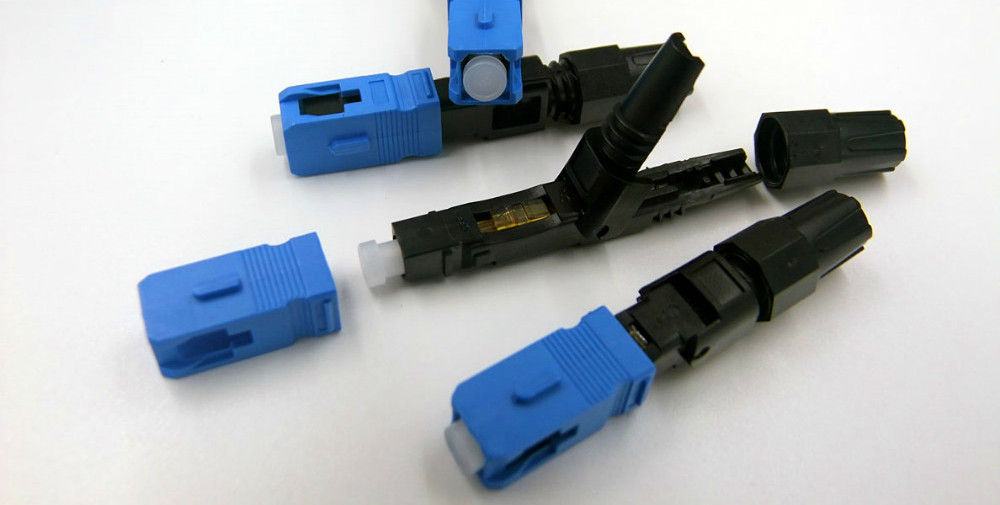

Field assembly connector is designed for simple and fast field termination of single fibers, without polishing or adhesives. The heart of the fast connector is a pre-polished ferrule and a mechanical splice inside the connector body. No electrical power supply is needed to assemble the field assembly fiber connector. Usually,Field Assembly Connectors is the most widely used fiber optic connector in FTTH application. It enables fast and on-site installation of 250 um, 900 um, 3.0 mm and 2.0 mm x 3.0 mm cable types. Two or three pieces of the preassembled and factory terminated connectors can be installed within 2 minutes using simple tools and can be reused several times. It accommodates a reliable and durable optical network especially suitable for advanced fiber optic systems requiring exceptional stability and low loss.

Assembly Principle of Field Assembly Connectors

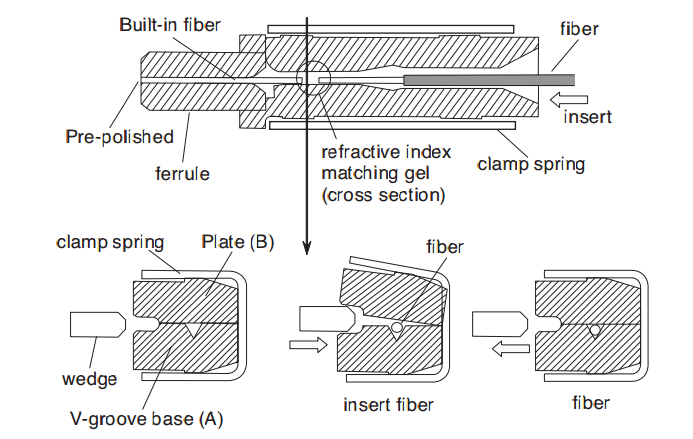

Picture below shows the internal structure of field assembly connector. Optical fiber is built into a ferrule of the connector, and the ferrule end face is polished in a factory. Moreover, to allow for the mechanical fixation of optical fiber, a mechanical splice is formed at the end of the ferrule. This mechanical splice is composed of plate A having a V groove, plate B which is flat above the V groove, and a clamp for the insertion of the two plates. The optical fiber has been positioned with high accuracy between the V groove and plate B, held securely by the spring power of the clamp. Built-in fiber endface contains refractive index matching gel whose refractive index is the almost same as glass, and thus this structure can realize stable fiber splicing without generating the discontinuity of the refractive index with the insertion fiber.

Assembly Process of Field Assembly Connectors

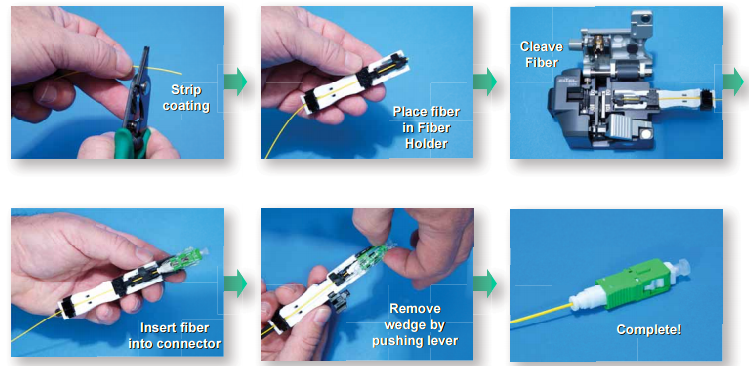

Assembly of the quick connector requires only normal fiber preparation tools: a fiber stripping tool, wipes and a fiber cleaver. No electrical power supply is needed. Just Strip the buffer, cleave and clean the fiber and then insert the fiber into the fast connector. Installation takes just minutes and couldn't be easier. Following picture gives an example for SC type fast connector installation steps.

Gelink Field Assembly Connectors Solution

The field assembly connector series are already a popular solution for optical wiring inside buildings and floors for LAN & CCTV applications and with the expansion of FTTH, is already proving itself to be the connector of choice by incumbents, municipalities, utilities & alternative carriers. Our field assembly connector series are now available in SC, LC, or FC variants, catering for 250um to 900um, and 2.0mm, 3.0mm diameter single-mode and multimode fiber types, including multimode 62.5/125um and multimode 50/125um. The single-mode versions are available with UPC or APC ferrules.